WAZAK

WAZAK - European quality shock absorbers

|

|

|

|

|

|

|||

|

|

||

|

|

||

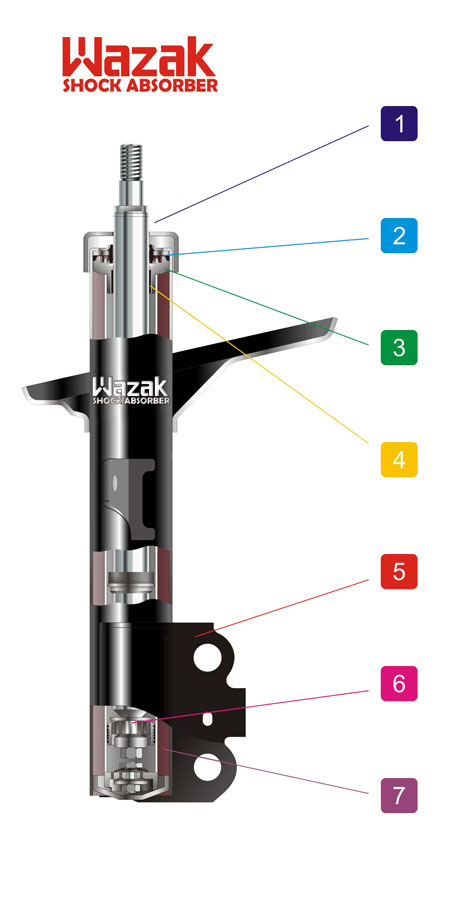

Description of the materials used in the production of WAZAK shock absorbers:

The rod

With years of experience in shock absorbers manufacturing and operating, as well as testing during the production process, we ensure the reliability and quality of the rods produced for WAZAK shock absorbers.

Rods for shock absorbers are chromium electroplated and polished with usage of German technology, thereby providing a low degree of friction, which significantly extends the sealing operating period.

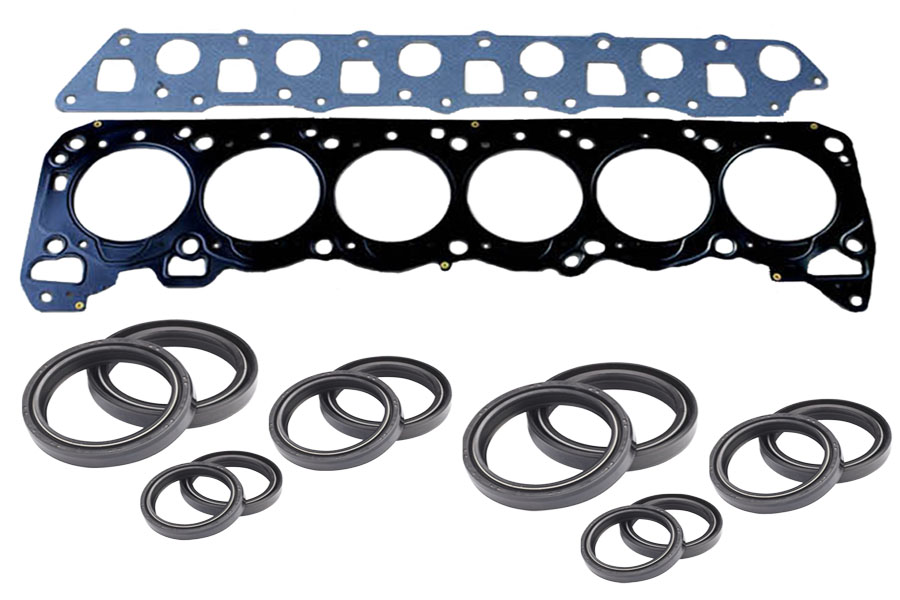

Seals

Sealing gaskets for WAZAK shock absorbers manufactured by NOK (Japan) - key partner in the global automotive industry.

Internal parts of the shock absorber

The use of high quality raw materials of powder metallurgy, as well as control during their mixing, compacting and powders baking ensures the quality and reliability of the final product s.

All internal parts of WAZAK shock absorbers coated with Teflon, which effectively increases durability and reduces friction.

Valve

There is three-stage valve system in WAZAK shock absorbers that allows it to adapt to any vertical accelerations of the wheel.

Metal blanks

Blanks for WAZAK shock absorbers stamped from high-quality steel with a high degree of corrosion protection.

WAZAK shock absorbers made of tubes with increased metal thickness. The inner surface of pipes passes through chromium-plating and multiple grinding, and also has a protective Teflon layer which provides the durability and long service life.

Paint finishes of the shock body

During the coating of the WAZAK shock absorbers body, the Korean paints are used that ensures excellent protection against corrosion.

Gas

WAZAK shock absorbers are filled with inert gas (nitrogen), which reduces oil foaming that in its turn gives confidence in handle ability and stability of the vehicle on the road.

Hydraulic oil

Hydraulic oil of Fuchs Company (Germany) is used in the production of the shock absorbers; the company is a leader in the production of motor and hydraulic oils.

Its high viscosity index allows adapt to large temperature differences. Working oil temperature is in the range between -45 to +100 C.

Shock absorbers and springs

Brake Shoes and Brake Pads

Clutch parts

Auto filters

Automotive Belts

Auto Electrics spare parts

Gaskets and seals

Body parts

Rubber auto parts

Bearings and tensioners

Steering Parts

Semi-axes, CV joints, CV Boots

Auto radiators

Water pumps, thermostats

Brake discs, brake hoses, wheel hubs

Cables, cylinders, sleeves

Spark plugs and glow plugs

Engine parts

Motor oils and technical fluids

Pulverizes and nozzles

Brake calipers

Starters and alternators

Car turbine

Exhaust system and parts